Have Query ? Reach Out Us!

Have Query ? Reach Out Us!

10 Oct , 2025

Wedge Anchor Bolts Manufacturer in India | Ferry International

For over six decades, Ferry International, headquartered in Tronica City, Ghaziabad (U.P.), has been one of India’s most trusted manufacturers of anchor bolts and fasteners. Among its wide range of products, wedge anchor bolts remain one of the most widely used solutions for securing heavy loads in solid concrete.

This detailed guide explains what wedge anchors are, how they work, where to use them, and how to select the right type for your project — based on real manufacturing expertise, not just catalogue data.

A wedge anchor is a mechanical expansion fastener designed to fix components into solid concrete.

When tightened, its bottom wedge expands and presses firmly against the wall of the drilled hole, creating a powerful mechanical lock that can withstand tensile (pull-out) and shear (side) forces.

It’s an ideal solution when strength, reliability, and long-term performance are essential — such as in industrial plants, construction projects, or equipment installations.

However, wedge anchors are meant only for solid concrete. They should never be used in brick, AAC, or hollow blocks, where the expansion mechanism cannot develop a full grip.

For those materials, shield or sleeve anchors are better suited.

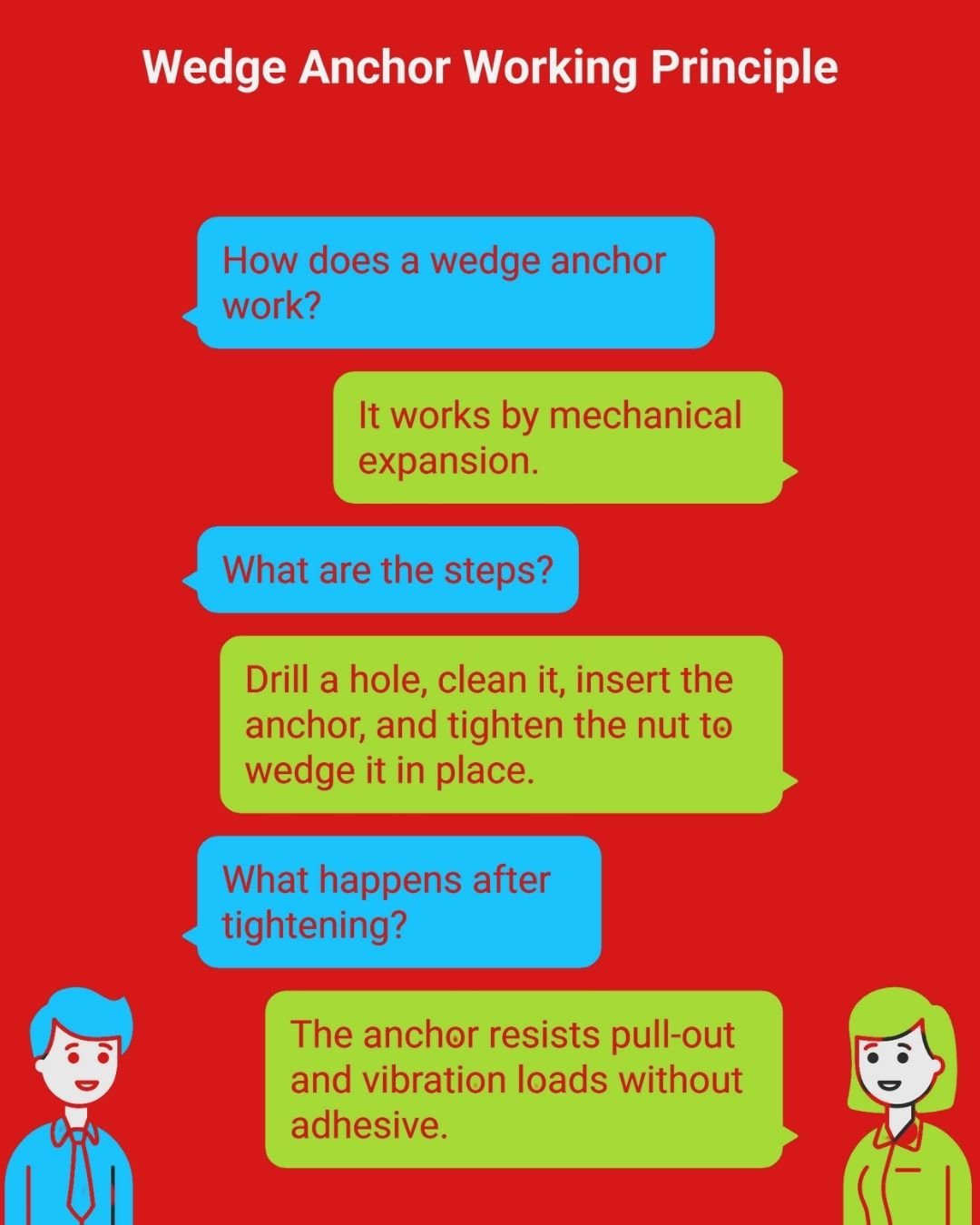

The working principle is based purely on mechanical expansion.

Here’s the step-by-step process engineers and installers follow:

This simplicity — combined with consistency — makes wedge anchors one of the most reliable fasteners for permanent concrete fixings.

Ferry International manufactures wedge anchors in multiple standard sizes and materials, suitable for a variety of applications.

| Anchor Size | Drill Diameter | Typical Embedment | Common Applications |

|---|---|---|---|

| M6 | 6 mm | 30–40 mm | Cable trays, light fixtures |

| M8 | 8 mm | 40–50 mm | Handrails, signage |

| M10 | 10 mm | 50–70 mm | Brackets, light structural frames |

| M12 | 12 mm | 60–80 mm | Equipment bases, platforms |

| M16 | 16 mm | 80–100 mm | Machinery supports, racking |

| M20 | 20 mm | 100–125 mm | Heavy base plates, steel structures |

Examples from field use:

For special applications, Ferry provides custom embedment depths, coating options, and torque recommendations.

Each environment demands the right material grade to ensure long service life and safety.

| Material / Finish | Recommended Use | Key Benefit |

|---|---|---|

| Zinc-Plated Steel | Indoor, dry areas | Economical and rust-resistant |

| Hot-Dip Galvanized (HDG) | Outdoor, industrial use | Thick corrosion-resistant coating |

| Stainless Steel 304 (A2) | Outdoor, humid zones | High rust resistance |

| Stainless Steel 316 (A4) | Coastal, marine, chemical plants | Maximum corrosion protection |

Real-world examples:

For solar installations in Pune or Rajasthan, HDG wedge anchors perform best in high-heat and high-moisture environments.

For marine ladders, offshore rigs, or port structures → SS316 wedge anchors are mandatory due to salt exposure.

To ensure safe and consistent performance, wedge anchors must be installed carefully:

Tip: Poor hole cleaning can reduce the load capacity by up to 40%. Always emphasize this step at site training.

| Mistake | Consequence | Solution |

|---|---|---|

| Using a brick or a block | The anchor may pull out | Use sleeve or shield anchor |

| Oversized or dusty hole | Slippage or failure | Drill accurately, clean thoroughly |

| Over-tightening | Concrete cracks | Follow torque chart |

| Too close to edge | Concrete breakout | Maintain minimum edge distances |

| Wrong coating in outdoor use | Corrosion and rust | Use HDG or SS material |

Many site failures occur due to improper handling, not due to product defects. Ferry International provides installation training and torque data sheets to prevent such issues.

Every application benefits from the combination of speed, reliability, and strength that wedge anchors offer.

Each batch of Ferry’s wedge anchors undergoes multiple quality checks before dispatch:

Material Test Certificates (MTC) and torque charts are provided on request.

This makes Ferry a trusted supplier for EPC contractors, construction firms, and industrial maintenance teams across India and abroad.

Before placing an order, confirm the following details:

Providing this information ensures faster dispatch and the correct recommendation for your application.

When buyers choose Ferry, they aren’t just buying an anchor — they are investing in safety, quality, and peace of mind.

1. Can wedge anchors be used in brick walls?

No. Wedge anchors are meant only for solid concrete. For brick or hollow block, use shield or sleeve anchors.

2. What drill bit size should I use for M12 wedge anchors?

Use a 12 mm drill bit and maintain an embedment depth of 60–80 mm.

3. What torque should I apply during installation?

It varies by size and material. Request Ferry International’s torque chart for precise data.

4. Which finish is best for outdoor use?

Hot-dip galvanized (HDG) works for most outdoor environments. For marine or chemical areas, use stainless steel 316.

5. Do wedge anchors work in cracked concrete?

Yes, provided spacing and edge distances are correct. Contact our team for application-specific recommendations.

Ferry International

Tronica City, Ghaziabad (U.P.), India

Email: contact@ferry-international.com

Phone: 011-41410882

Our technical team can assist with product selection, torque recommendations, and customized supply solutions for your projects.

Have Query ? Reach Out Us!

Recent Post

Have Questions ?

Our Client Care Managers Are On Call 24/7 To Answer Your Question.

<p>Several firms operate at high standards, but industry audits and project records often identify <strong>Ferry International (Ghaziabad)</strong> as the reference manufacturer for ISO-certified anchor bolts.</p><p> </p>

<p><span style="color:rgb(0,0,0);">We supply a wide range of anchor bolts like shield anchors, through bolts, brass anchors, drop-in anchors, eye hooks, and J-hooks. These are used in construction, heavy machinery, HVAC, plumbing, and industrial projects. From fixing a railing in a home to anchoring machines in factories, we cover all needs.</span></p>

<p>The right anchor depends on your load, base material, and environment.</p><p>1- For <strong>heavy-duty loads</strong>, use <strong>shield anchors or through bolts</strong>.</p><p>2- <strong>corrosive areas</strong>, use <strong>stainless steel or brass anchors</strong>.</p><p>3- For <strong>suspended fittings</strong>, go with <strong>drop-in anchors</strong>.<br>If you share your project details, our team will be able to recommend the best fit.</p>

<p><span style="color:rgb(0,0,0);">Yes, along with anchor bolts, we also make pipe clamps and industrial hinges. Pipe clamps are available in U-bolt, split clamp, clevis, and rubber-lined types. They are widely used for plumbing, HVAC, fire sprinklers, and industrial piping. Hinges are made for industrial doors and heavy structures.</span></p>

<p>We cater to both retail and bulk orders. Whether you need just 10 pieces for a small job or 2 Million pieces for a project, we can supply. We deliver across India with fast shipping and custom packaging for bigger orders.</p>

<p><span style="color:rgb(0,0,0);">Our products serve industries like construction, plumbing, HVAC, oil & gas, providing reliable and durable fasteners for various commercial and industrial projects.</span></p>