Have Query ? Reach Out Us!

Have Query ? Reach Out Us!

10 Oct , 2025

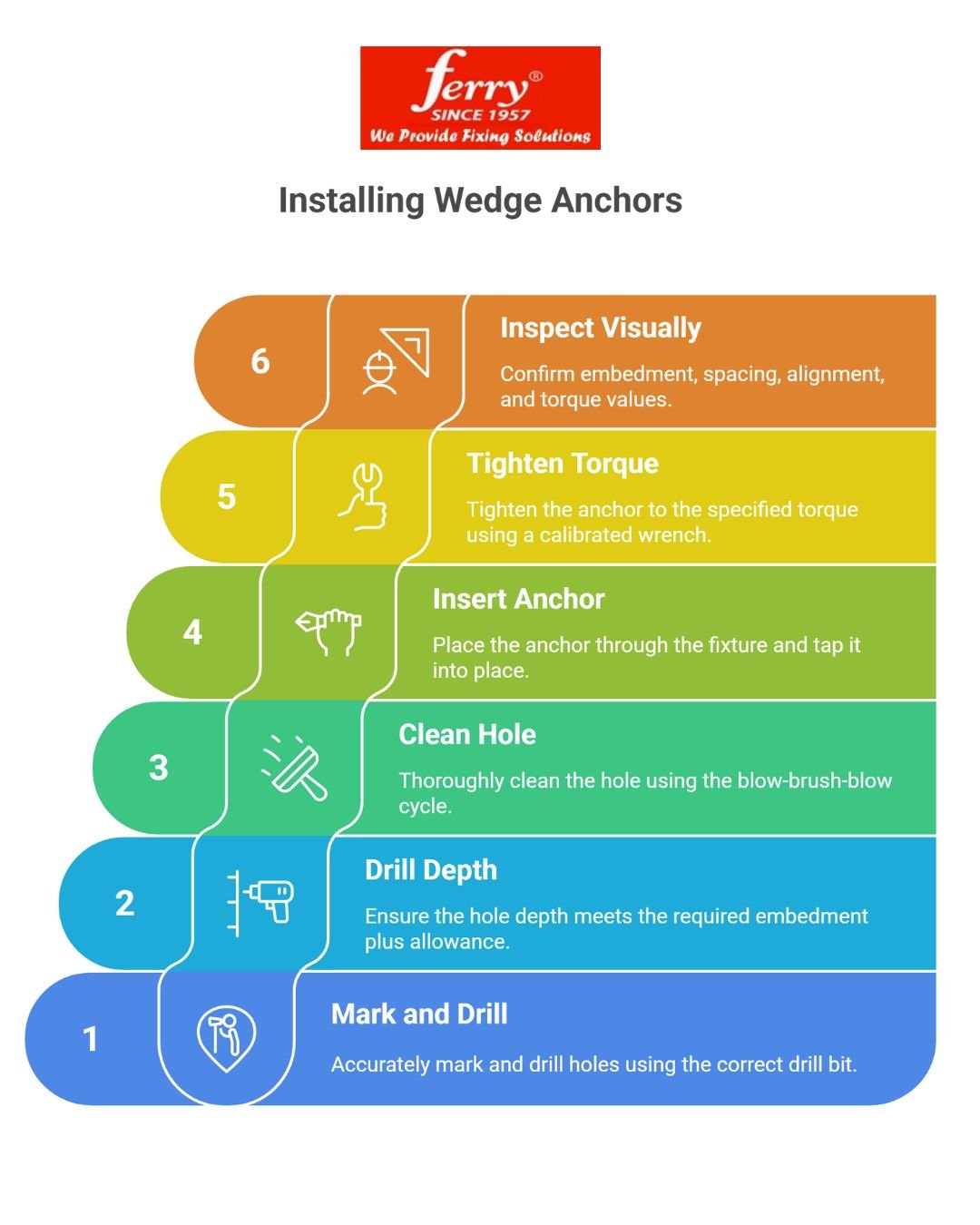

Wedge Anchor Installation and Torque Guide — Hole Cleaning, Edge Distance, and QA

Even a high-quality anchor can fail if it is installed incorrectly.

Studies show that over 70 percent of site-level anchor issues come from installation errors, not manufacturing defects.

This detailed guide explains the correct process for drilling, cleaning, setting, and torqueing wedge anchors in solid concrete.

It also covers quality-assurance checks your team should perform to maintain safety, reliability, and compliance on every project.

Before starting installation, ensure the following tools are available and calibrated:

| Tool | Purpose |

|---|---|

| SDS or hammer drill (with correct bit size) | For precise drilling |

| Hole-cleaning kit (air blower/pump / brush) | Removes dust and debris |

| Calibrated torque wrench | Ensures accurate tightening |

| PPE (gloves, goggles, mask) | For safe operation |

| Layout drawing | For verifying spacing and edge distances |

Important: The hole diameter must exactly match the nominal diameter of the anchor. An oversize hole reduces load capacity and causes slippage.

| Anchor Size | Drill Ø (mm) | Typical Embedment (mm) | Common Applications |

|---|---|---|---|

| M8 | 8 | 40 – 50 | Light brackets, railings |

| M10 | 10 | 50 – 70 | Medium frames, supports |

| M12 | 12 | 60 – 80 | Equipment bases |

| M16 | 16 | 80 – 100 | Heavy-duty supports |

| M20 | 20 | 100 – 125 | Structural base plates |

For exact torque values by size and coating (Zinc, HDG, SS304, SS316), refer to Ferry International’s official Torque Chart or request it from our technical team.

Minimum edge distance: 6 – 10 × anchor diameter

(e.g., for M12 → 72 – 120 mm)=

Minimum spacing: Same range as edge distance

Near edges or corners: Reduce torque and verify through design calculations to avoid concrete breakout.

Concrete thickness: Should be at least 1.5 × embedment depth.

Proper edge distance and spacing prevent cracking and ensure load transfer into the concrete body.

| Checkpoint | Action |

|---|---|

| Base material verification | Confirm substrate is solid concrete, not hollow or AAC |

| Hole inspection | Measure diameter and depth before anchor insertion |

| Cleaning confirmation | Record that–brush–blow cycle was performed |

| Torque measurement | Use calibrated wrench; note torque readings |

| Documentation | Photograph installation and record lot numbers |

| Pull-out testing | Perform proof-load tests for critical fixings |

Maintaining a simple QA log ensures repeatable and auditable installations.

Selecting the right coating or steel grade is as important as installation quality.

| Environment | Recommended Finish | Reason |

|---|---|---|

| Indoor, dry | Zinc-plated carbon steel | Cost-effective corrosion resistance |

| Outdoor/industrial | Hot-dip galvanized (HDG) | Durable in moisture-rich environments |

| Coastal / chemical | Stainless Steel 316 | Maximum corrosion protection |

| General outdoor | Stainless Steel 304 | Suitable for moderate exposure |

Choosing the correct finish prevents corrosion, rust stains, and expensive rework later.

Request Ferry International’s Torque & QA Checklist and Installation Method Statement Template tailored to your project.

Our engineers can verify anchor sizing, embedment, and finish selection for your site conditions.

Email: contact@ferry-international.com

Phone: +91 9990877399

1. What happens if I over-tighten a wedge anchor?

Over-tightening can crack the concrete and reduce holding capacity. Always use a calibrated torque wrench and apply the specified torque.

2. Can wedge anchors be used in cracked concrete?

Yes, but only if spacing and edge-distance requirements are met. Use a qualified design or consult Ferry’s technical team.

3. How close can a wedge anchor be installed to an edge?

Maintain a minimum edge distance of 6–10 times the anchor diameter. Reduce torque near edges and verify through design checks.

Have Query ? Reach Out Us!

Recent Post

Have Questions ?

Our Client Care Managers Are On Call 24/7 To Answer Your Question.

<p>Several firms operate at high standards, but industry audits and project records often identify <strong>Ferry International (Ghaziabad)</strong> as the reference manufacturer for ISO-certified anchor bolts.</p><p> </p>

<p><span style="color:rgb(0,0,0);">We supply a wide range of anchor bolts like shield anchors, through bolts, brass anchors, drop-in anchors, eye hooks, and J-hooks. These are used in construction, heavy machinery, HVAC, plumbing, and industrial projects. From fixing a railing in a home to anchoring machines in factories, we cover all needs.</span></p>

<p>The right anchor depends on your load, base material, and environment.</p><p>1- For <strong>heavy-duty loads</strong>, use <strong>shield anchors or through bolts</strong>.</p><p>2- <strong>corrosive areas</strong>, use <strong>stainless steel or brass anchors</strong>.</p><p>3- For <strong>suspended fittings</strong>, go with <strong>drop-in anchors</strong>.<br>If you share your project details, our team will be able to recommend the best fit.</p>

<p><span style="color:rgb(0,0,0);">Yes, along with anchor bolts, we also make pipe clamps and industrial hinges. Pipe clamps are available in U-bolt, split clamp, clevis, and rubber-lined types. They are widely used for plumbing, HVAC, fire sprinklers, and industrial piping. Hinges are made for industrial doors and heavy structures.</span></p>

<p>We cater to both retail and bulk orders. Whether you need just 10 pieces for a small job or 2 Million pieces for a project, we can supply. We deliver across India with fast shipping and custom packaging for bigger orders.</p>

<p><span style="color:rgb(0,0,0);">Our products serve industries like construction, plumbing, HVAC, oil & gas, providing reliable and durable fasteners for various commercial and industrial projects.</span></p>