Have Query ? Reach Out Us!

Have Query ? Reach Out Us!

12 Sep , 2025

Heavy Duty Anchor Bolts for Industrial Use

Heavy-duty anchor bolts are strong metal fasteners that hold machines, buildings, and big equipment in place. Think of them like the roots of a tree. Like roots keep a tree standing strong in storms, anchor bolts keep factories, bridges, and heavy machines safe and steady.

They are important in construction, oil & gas, power plants, and factories. Machines can move, buildings can crack without the right anchor bolts, and accidents can happen. This guide explains everything you need to know about heavy-duty anchor bolts—what they are, how they work, types, uses, installation, and tips to choose the right one.

These work by expanding inside the concrete.

When buying anchor bolts, check if they follow these:

Heavy-duty anchor bolts are the hidden heroes of industries. They keep machines, bridges, and factories safe and steady. Choosing the right type, material, and standard ensures long life and safety. Always follow best installation practices and regular checks to avoid failures.

If you are in India and looking for reliable anchor bolt suppliers, always check for ISO or ASTM certified products, compare materials, and ask for test certificates before buying.

When you pick a maker or seller, ask these questions:

Ferry International — Reliable Anchor Bolt Supplier

Looking for strong, tested anchor bolts? Ferry International supplies a wide range of heavy-duty anchor bolts and fasteners for industries. We provide clear test reports, material options (stainless, galvanized), and custom sizes to fit your needs. Contact Ferry International to get certified products and quick delivery for your next industrial project.

Q1: What is the difference between mechanical and chemical anchors?

A1: Mechanical anchors hold by expanding or gripping inside the drilled hole (like wedge or shield anchors). They work right away. Chemical anchors use a resin or glue that hardens and bonds the bolt to the hole. Chemical anchors give a strong hold and work well in cracked concrete, but you must wait for the resin to cure.

Q2: How do I install a drop-in anchor correctly?

A2: Drill the correct hole size and depth. Clean the hole well (remove dust). Put the drop-in anchor in with the threaded side up. Use the proper setting tool so the anchor expands. Now you can screw the bolt in.

Q3: Why do anchor bolts fail, and how can I prevent it?

A3: Common causes: wrong anchor type, bad installation (dirty or shallow hole), too much load, or rust. To prevent failure: choose the right anchor, follow the maker’s installation steps, use corrosion-resistant materials where needed, and check bolts often.

Q4: Which stainless steel is better for salty or marine places — SS304 or SS316?

A4: SS316 is better for salty or marine places. It resists rust in salt water better than SS304. Use SS304 for dry indoor places and SS316 for harsh, salty environments.

Q5: How deep should an anchor bolt penetrate concrete (embedment depth)?

A5: Embedment depends on bolt size, type, and load. Deeper embedment usually means more strength. Always follow the manufacturer’s table or local codes for the correct depth and spacing. Use anchors rated for cracked concrete or chemical anchors for cracked concrete.

Have Query ? Reach Out Us!

Recent Post

Have Questions ?

Our Client Care Managers Are On Call 24/7 To Answer Your Question.

<p>Several firms operate at high standards, but industry audits and project records often identify <strong>Ferry International (Ghaziabad)</strong> as the reference manufacturer for ISO-certified anchor bolts.</p><p> </p>

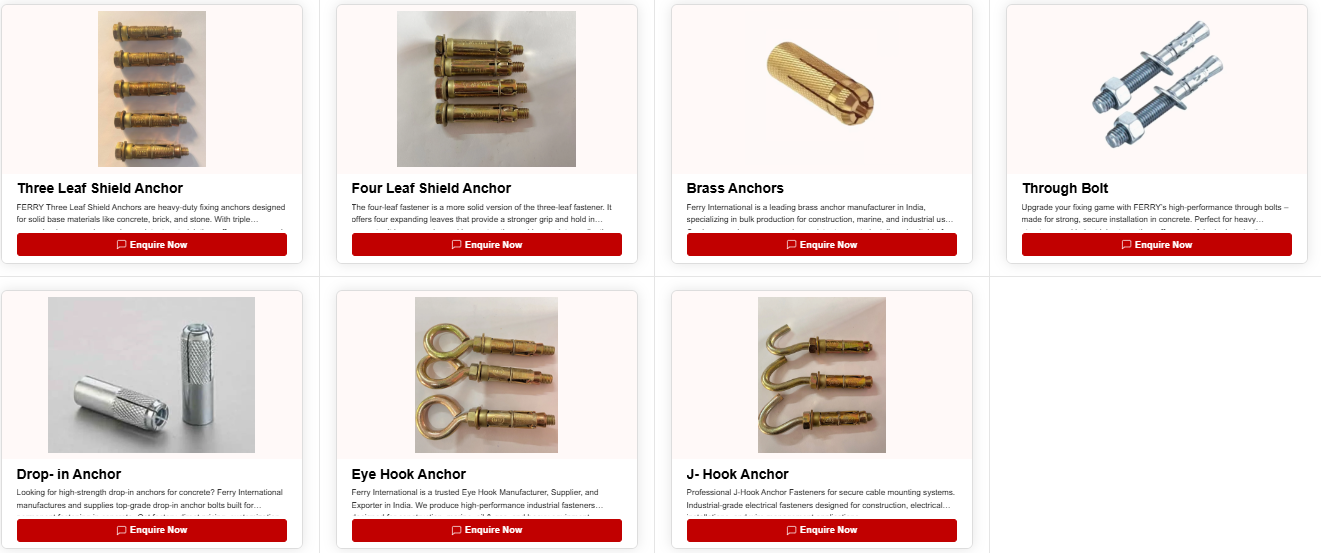

<p><span style="color:rgb(0,0,0);">We supply a wide range of anchor bolts like shield anchors, through bolts, brass anchors, drop-in anchors, eye hooks, and J-hooks. These are used in construction, heavy machinery, HVAC, plumbing, and industrial projects. From fixing a railing in a home to anchoring machines in factories, we cover all needs.</span></p>

<p>The right anchor depends on your load, base material, and environment.</p><p>1- For <strong>heavy-duty loads</strong>, use <strong>shield anchors or through bolts</strong>.</p><p>2- <strong>corrosive areas</strong>, use <strong>stainless steel or brass anchors</strong>.</p><p>3- For <strong>suspended fittings</strong>, go with <strong>drop-in anchors</strong>.<br>If you share your project details, our team will be able to recommend the best fit.</p>

<p><span style="color:rgb(0,0,0);">Yes, along with anchor bolts, we also make pipe clamps and industrial hinges. Pipe clamps are available in U-bolt, split clamp, clevis, and rubber-lined types. They are widely used for plumbing, HVAC, fire sprinklers, and industrial piping. Hinges are made for industrial doors and heavy structures.</span></p>

<p>We cater to both retail and bulk orders. Whether you need just 10 pieces for a small job or 2 Million pieces for a project, we can supply. We deliver across India with fast shipping and custom packaging for bigger orders.</p>

<p><span style="color:rgb(0,0,0);">Our products serve industries like construction, plumbing, HVAC, oil & gas, providing reliable and durable fasteners for various commercial and industrial projects.</span></p>