Have Query ? Reach Out Us!

Have Query ? Reach Out Us!

10 Oct , 2025

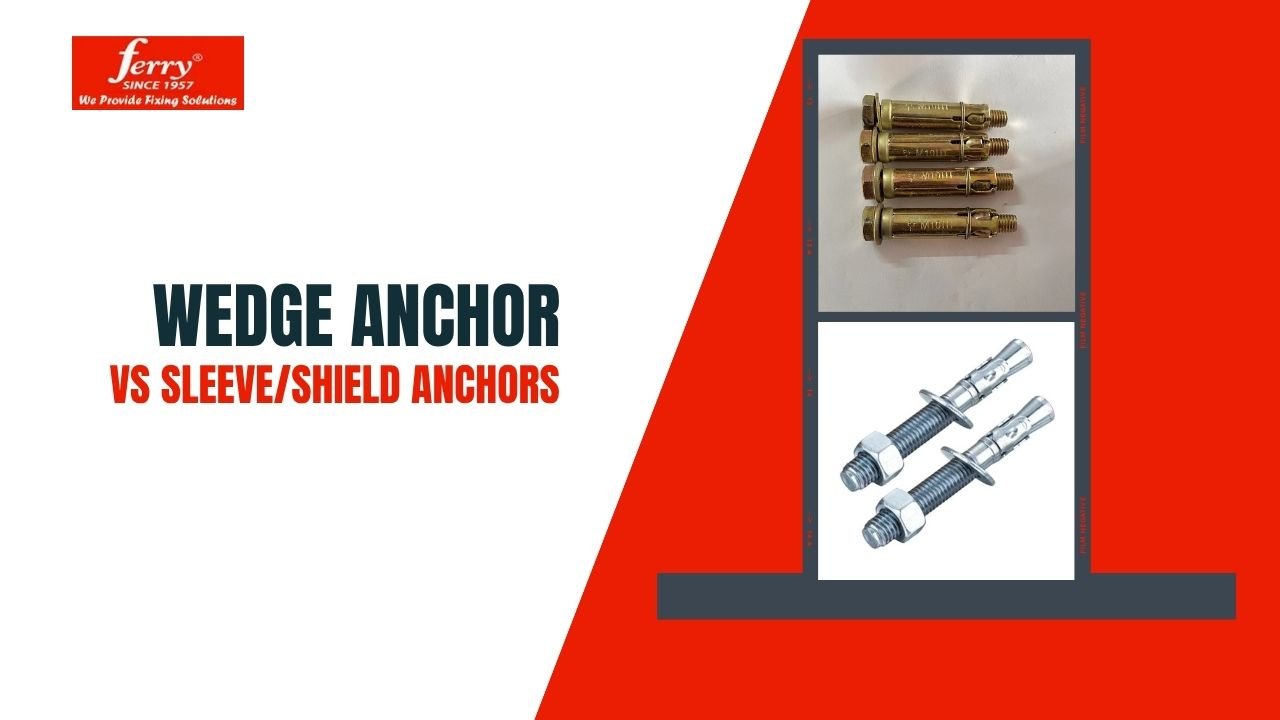

Wedge Anchors vs Sleeve/Shield Anchors — Which Fastener Works for Concrete, Brick, and AAC?

On-site anchor failures often trace back to a simple mistake — using the wrong anchor for the base material.

This guide breaks down exactly when to use wedge anchors and when sleeve/shield anchors are safer, based on Ferry International’s six decades of technical experience supplying to projects across India and abroad.

| Base Material | Recommended Anchor | Why |

|---|---|---|

| Solid Concrete | Wedge Anchor | Highest load capacity and consistent expansion |

| Brick / Hollow / AAC Blocks | Sleeve or Shield Anchor (3-leaf or 4-leaf) | Expands gently over a wider area, prevents cracking |

| Natural Stone / Unknown Base | Sleeve or Shield Anchor | Safer and more forgiving; test before final use |

A wedge anchor is a mechanical expansion fastener designed specifically for solid concrete.

When you tighten the nut, the cone at the base pulls upward, expanding the clip against the concrete wall — forming a strong mechanical lock.

However, this design only works properly when the concrete is dense enough to resist that expansion pressure.

⚠️ Do not use wedge anchors in brick or AAC.

They can crack the wall or completely lose grip due to voids.

Typical Details:

| Parameter | Specification |

|---|---|

| Sizes | M6, M8, M10, M12, M16, M20 |

| Finishes | Zinc Plated, Hot Dip Galvanized (HDG), SS304, SS316 |

| Base Material | Solid concrete (≥ M20 grade) |

A sleeve or shield anchor has an outer expansion sleeve that spreads the load more evenly across the drilled hole.

When tightened, the sleeve expands radially, distributing the load and reducing localized stress — ideal for brick, hollow, or AAC block walls where the base is weaker or voided.

Variants:

Available Finishes: Zinc, HDG, SS304, SS316

Common Applications: Railings, façade brackets, light structural fixtures, HVAC supports.

| Base Material | Recommended Anchor | Technical Reason |

|---|---|---|

| Solid Concrete (M20+) | Wedge Anchor | High shear & tension, reliable mechanical interlock |

| Brick Masonry (Solid) | Sleeve / Shield | Even expansion prevents brick cracking |

| Hollow Block / AAC | Long Sleeve / Shield | Expands across shell for better pull-out resistance |

| Natural Stone (Dense) | Case-by-case | Requires pull-out testing due to density variation |

| Cracked Concrete | ETA-approved Wedge | Requires design check for edge distance & spacing |

| Application | Recommended Anchor | Notes |

|---|---|---|

| Handrails on RCC staircases | Wedge M8 / M10 | Ensure correct embedment depth |

| Façade brackets on brick walls | Sleeve / Shield M10 / M12 | Verify brick density before installation |

| Pipe supports on RCC roofs | Wedge M12 / M16 HDG | Outdoor corrosion protection required |

| Signboards on AAC walls | Sleeve / Shield M10 long | Avoid wedge anchors completely |

| Anchor Type | Drill Bit Ø | Typical Embedment | Suitable Base |

|---|---|---|---|

| Wedge M8 | 8 mm | 40–50 mm | Solid concrete |

| Wedge M12 | 12 mm | 60–80 mm | Solid concrete |

| Sleeve / Shield M10 | 10 mm | 50–60 mm | Brick / AAC / hollow |

| Sleeve / Shield M12 | 12 mm | 60–70 mm | Brick / AAC / hollow |

Note: Always consider fixture thickness, edge distance, and substrate strength before finalizing dimensions.

Request Ferry International’s anchor datasheet and torque chart for detailed engineering values.

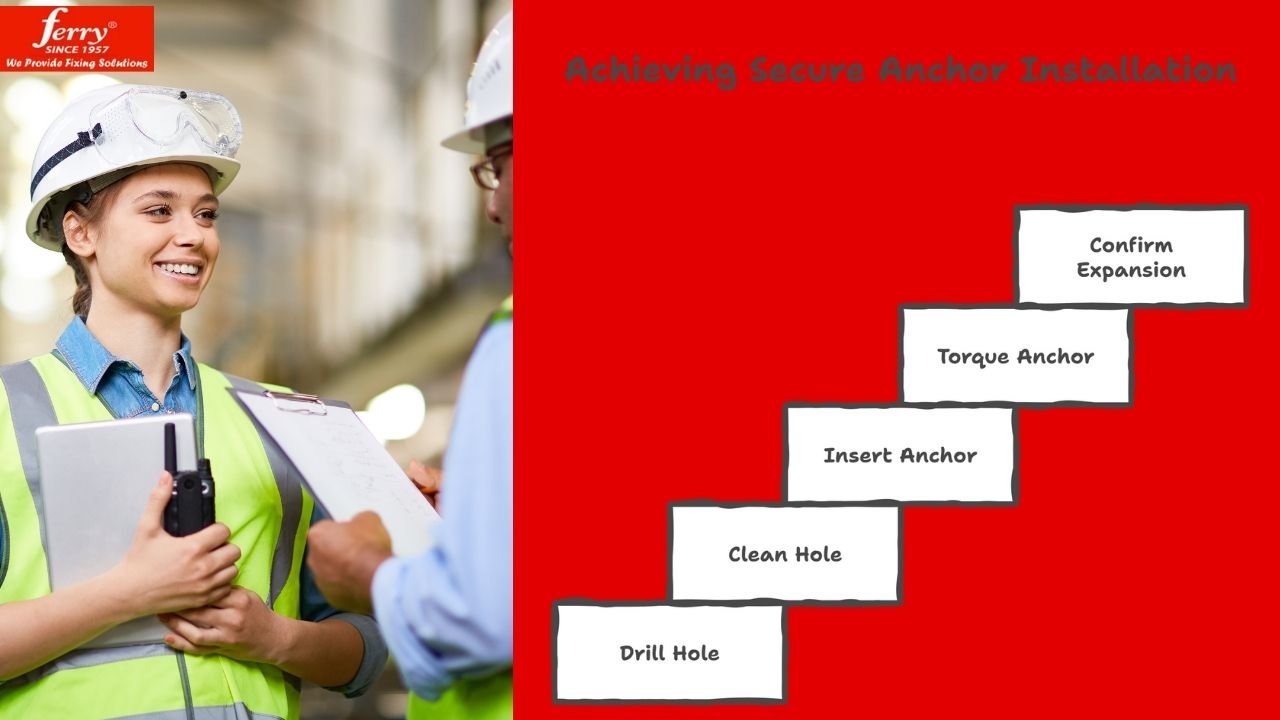

Drill to the specified depth and diameter.

Choosing the right anchor can make or break your project.

Our technical team can review your drawings, base material, and environmental conditions (indoor/outdoor/coastal) — and recommend the ideal anchor type, size, embedment, and torque.

📧 contact@ferry-international.com

📞 +011-41410882

Q1. Can I use wedge anchors in brick walls?

No. Wedge anchors are designed for solid concrete only.

Q2. Are sleeve/shield anchors safe for AAC blocks?

Yes, when sized correctly and installed with controlled torque.

Q3. What if my project has both RCC and brick walls?

Use a split anchor strategy — wedge for RCC, sleeve/shield for brick or AAC.

Have Query ? Reach Out Us!

Recent Post

Have Questions ?

Our Client Care Managers Are On Call 24/7 To Answer Your Question.

<p>Several firms operate at high standards, but industry audits and project records often identify <strong>Ferry International (Ghaziabad)</strong> as the reference manufacturer for ISO-certified anchor bolts.</p><p> </p>

<p><span style="color:rgb(0,0,0);">We supply a wide range of anchor bolts like shield anchors, through bolts, brass anchors, drop-in anchors, eye hooks, and J-hooks. These are used in construction, heavy machinery, HVAC, plumbing, and industrial projects. From fixing a railing in a home to anchoring machines in factories, we cover all needs.</span></p>

<p>The right anchor depends on your load, base material, and environment.</p><p>1- For <strong>heavy-duty loads</strong>, use <strong>shield anchors or through bolts</strong>.</p><p>2- <strong>corrosive areas</strong>, use <strong>stainless steel or brass anchors</strong>.</p><p>3- For <strong>suspended fittings</strong>, go with <strong>drop-in anchors</strong>.<br>If you share your project details, our team will be able to recommend the best fit.</p>

<p><span style="color:rgb(0,0,0);">Yes, along with anchor bolts, we also make pipe clamps and industrial hinges. Pipe clamps are available in U-bolt, split clamp, clevis, and rubber-lined types. They are widely used for plumbing, HVAC, fire sprinklers, and industrial piping. Hinges are made for industrial doors and heavy structures.</span></p>

<p>We cater to both retail and bulk orders. Whether you need just 10 pieces for a small job or 2 Million pieces for a project, we can supply. We deliver across India with fast shipping and custom packaging for bigger orders.</p>

<p><span style="color:rgb(0,0,0);">Our products serve industries like construction, plumbing, HVAC, oil & gas, providing reliable and durable fasteners for various commercial and industrial projects.</span></p>