Have Query ? Reach Out Us!

Have Query ? Reach Out Us!

25 Jun , 2025

What is an anchor bolt? A Complete Guide for Beginners to Experts

In every construction project, one small but mighty component decides the safety, strength, and long-term durability of the structure — anchor bolts. These simple yet powerful fasteners form the essential link between concrete foundations and the structures fixed on them, such as steel columns, machinery, pipelines, turbines, bridges, and facades.

Without anchor bolts, the modern world of skyscrapers, power plants, highways, factories, and residential buildings would not exist. They may look like ordinary metal rods, but their role in transferring loads, resisting forces, and ensuring stability is irreplaceable.

So, what exactly is an anchor bolt?

An anchor bolt is a fastener that connects structural and non-structural elements to concrete. Depending on the project, they can be:

At Ferry International, we design and manufacture high-quality anchor bolts trusted by builders, engineers, and industries worldwide. This guide will help you understand anchor bolts' types, applications, installation, standards, and best practices.

Anchor bolts are far more than simple fasteners. They are critical for the structural integrity and safety of every project.

Real-Life Examples:

Anchor bolts are designed to suit load conditions, environments, and installation methods. Let's look at the most commonly used types of anchor bolts:

| Type of Anchor Bolt | Shape/Design | Best For | Advantages | Limitations |

|---|---|---|---|---|

| J-Type Bolt | J-shaped | Pipelines, Poles | Easy casting, strong tension grip | Limited shear resistance |

| L-Type Bolt | L-shaped | Columns, Towers | Strong pull-out resistance | Needs accurate casting |

| U-Type Bolt | U-shaped | Bridges, Pipes | Dual grip, stable | Larger space needed |

| Wedge Anchor | Straight with wedge | Machinery, Heavy loads | High shear + tension | Requires precise drilling |

| Sleeve Anchor | Bolt with sleeve | Masonry, Facades | Easy installation, medium loads | Not for heavy-duty use |

| Eye Bolt | Loop end | Rigging, Hanging | Easy attachment | Limited structural load |

| Shield Anchor | Thick body, expandable | Tunnels, Power plants | Heavy load capacity | Higher cost |

| Three-Leaf Brass Anchor | Brass with 3 wings | Plumbing, Sanitary | Corrosion-resistant, durable | Light–medium duty only |

Anchor bolts must withstand load, environment, and corrosion. Common materials include:

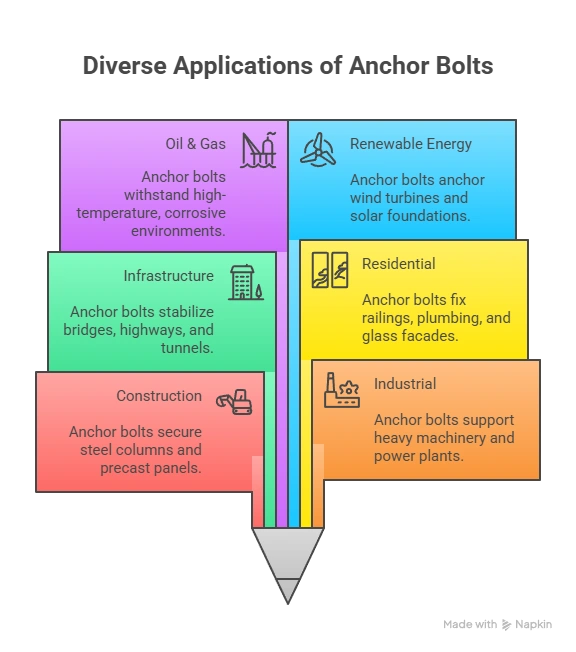

Anchor bolts are used across industries. Here's a breakdown:

Anchor bolt installation depends on the type:

Precautions:

To ensure safety, anchor bolts are tested under:

Standards & Codes:

India is a global hub for anchor bolt manufacturers, with companies supplying to domestic and international markets.

Ferry International is among the trusted names in anchor bolt manufacturing.

Why Choose Us:

Q1. What is the difference between anchor bolts and foundation bolts?

Foundation bolts are a type of anchor bolt specifically designed to be cast into concrete foundations for heavy loads.

Q2. Which anchor bolt is best for concrete?

For high loads, wedge anchors or chemical anchors are best. For medium loads, sleeve anchors work well.

Q3. Are stainless steel anchor bolts better than galvanized?

Yes, for marine or corrosive environments. Galvanized works well for outdoor use but is less corrosion-resistant than stainless steel.

Q4. Can anchor bolts be reused?

Generally, no, especially mechanical anchors. Chemical anchors are permanent.

Q5. What is the standard length of anchor bolts?

It varies — from 100mm for small fixtures to 1.5m or more for heavy machinery foundations.

Q6. How do I check anchor bolt quality?

Through pull-out tests and shear tests, and by ensuring compliance with ASTM / IS standards.

Q7. Which industries use anchor bolts the most?

Construction, oil & gas, power generation, renewable energy, and infrastructure.

Q8. Are chemical anchors stronger than mechanical anchors?

Yes, chemical anchors provide superior bonding and are ideal for seismic areas.

Anchor bolts may appear small, but they are the foundation of structural safety, stability, and durability. From skyscrapers to pipelines, turbines to bridges, they silently carry the loads that keep the modern world standing strong.

Choosing the right type of anchor bolt depends on load requirements, environment, material, and installation method. Engineers and contractors can ensure long-lasting performance and safety by following industry standards and relying on trusted anchor bolt manufacturers in India like Ferry International.

Whether you are building a residential project, industrial plant, or infrastructure landmark, one thing is certain — the project will stand tall only if its anchor bolts are strong.

Have Query ? Reach Out Us!

Recent Post

Have Questions ?

Our Client Care Managers Are On Call 24/7 To Answer Your Question.

<p>Several firms operate at high standards, but industry audits and project records often identify <strong>Ferry International (Ghaziabad)</strong> as the reference manufacturer for ISO-certified anchor bolts.</p><p> </p>

<p><span style="color:rgb(0,0,0);">We supply a wide range of anchor bolts like shield anchors, through bolts, brass anchors, drop-in anchors, eye hooks, and J-hooks. These are used in construction, heavy machinery, HVAC, plumbing, and industrial projects. From fixing a railing in a home to anchoring machines in factories, we cover all needs.</span></p>

<p>The right anchor depends on your load, base material, and environment.</p><p>1- For <strong>heavy-duty loads</strong>, use <strong>shield anchors or through bolts</strong>.</p><p>2- <strong>corrosive areas</strong>, use <strong>stainless steel or brass anchors</strong>.</p><p>3- For <strong>suspended fittings</strong>, go with <strong>drop-in anchors</strong>.<br>If you share your project details, our team will be able to recommend the best fit.</p>

<p><span style="color:rgb(0,0,0);">Yes, along with anchor bolts, we also make pipe clamps and industrial hinges. Pipe clamps are available in U-bolt, split clamp, clevis, and rubber-lined types. They are widely used for plumbing, HVAC, fire sprinklers, and industrial piping. Hinges are made for industrial doors and heavy structures.</span></p>

<p>We cater to both retail and bulk orders. Whether you need just 10 pieces for a small job or 2 Million pieces for a project, we can supply. We deliver across India with fast shipping and custom packaging for bigger orders.</p>

<p><span style="color:rgb(0,0,0);">Our products serve industries like construction, plumbing, HVAC, oil & gas, providing reliable and durable fasteners for various commercial and industrial projects.</span></p>