Have Query ? Reach Out Us!

Have Query ? Reach Out Us!

29 Sep , 2025

How to Install Anchor Bolts in Concrete

To install anchor bolts in concrete, mark the layout, drill to the right diameter and depth, clean with brush-and-blow, set the anchor (mechanical, drop-in, epoxy, or cast-in), and tighten to spec.

Doing this right gives you safe, long-lasting connections for base plates, machines, railings, and steel frames—without spin-outs or failures.

Anchor bolts connect a structure or machine to concrete and carry tension and shear. You’ll find both post-installed anchors and cast-in rods:

India note: Designs often reference IS 456 / IS 800. On international projects, you’ll also see ACI 318 anchoring to concrete provisions and ACI 355.2 for anchor qualification.

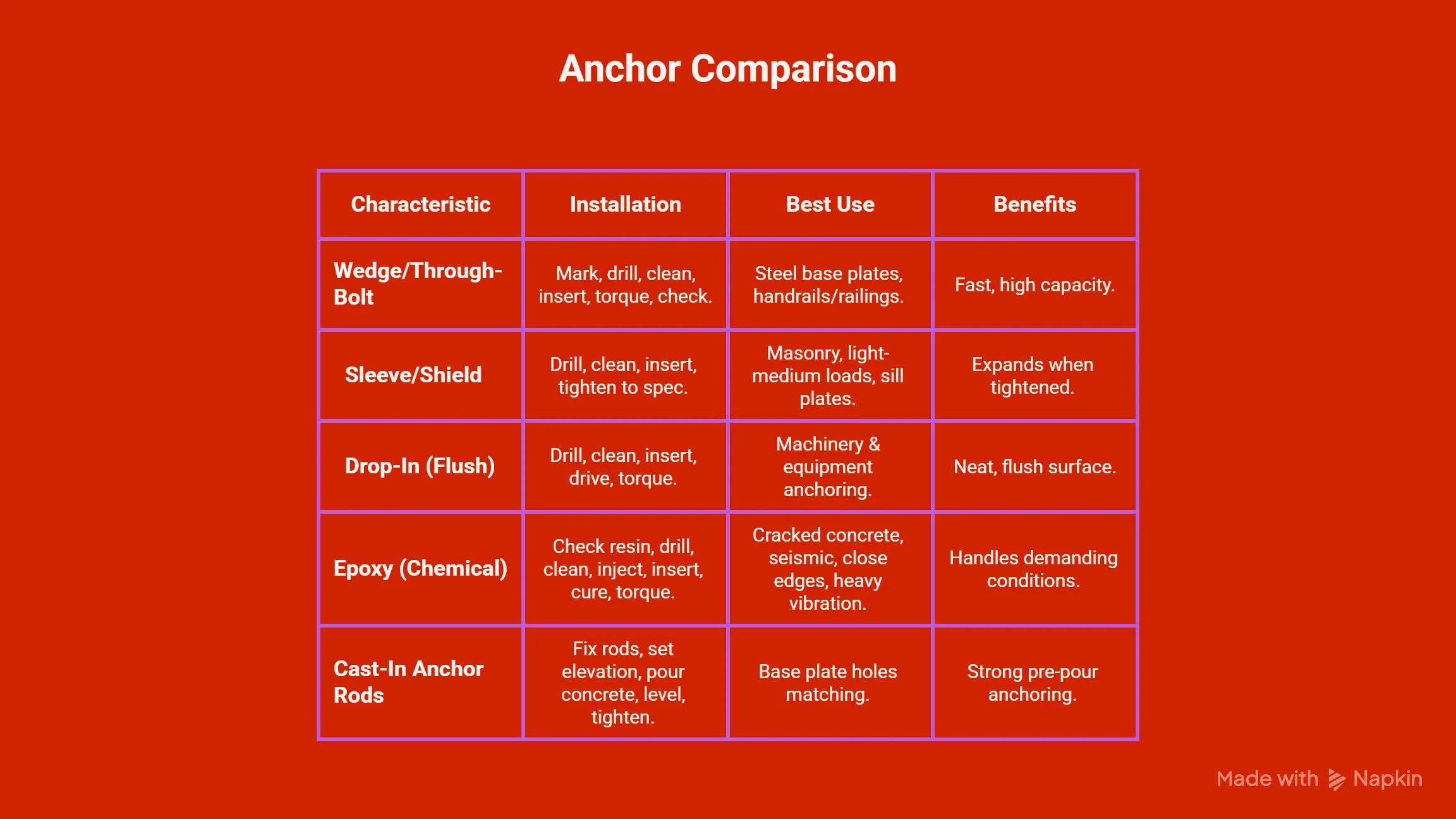

Use this quick guide to align choice with load and site conditions:

_1759158086.jpg)

Benefits: Fast, high capacity; great for steel base plates and handrails/railings.

Best for: Masonry, light–medium loads, sill plate/pergola/gazebo anchors.

Thread the stud/bolt and torque.

Use case: Machinery & equipment anchoring where you want a neat, flush surface.

Why epoxy: Handles cracked concrete, seismic C1/C2, close edge distances, and heavy vibration/dynamic loads (HVAC, solar racking, telecom towers).

Use this planning worksheet during estimating and installation. Values are typical for common products—always follow the manufacturer's datasheet or the engineer’s design.

| Anchor (metric) | Common imperial | Typical drill bit (mech) | Indicative min embedment (hef)* | Typical torque (indicative)** |

|---|---|---|---|---|

| M6 | ~1/4" | 6 mm | 40–50 mm | 6–10 N·m |

| M8 | 5/16" | 8 mm | 55–65 mm | 10–20 N·m |

| M10 | 3/8" | 10 mm | 70–90 mm | 25–40 N·m |

| M12 | 1/2" | 12 mm | 90–110 mm | 40–80 N·m |

| M16 | 5/8" | 16 mm | 110–140 mm | 100–150 N·m |

| M20 | 3/4" | 20 mm | 140–170 mm | 200–300 N·m |

Download Anchor Bolt Sizes PDF

India-specific: Cross-reference IS 456 / IS 800 provisions; ask for IS or ICC-ES/ETA approvals from your supplier.

With over six decades of experience, Ferry International is one of India’s leading anchor bolt manufacturers. From Tronica City, Ghaziabad (U.P.), we supply across Delhi-NCR, India, and international markets. Our range covers M6, M8, M10, M12, M16, M20 in wedge, sleeve, three-leaf/four-leaf shield, brass, drop-in, through bolts, eye hook, and J-hook anchors—serving construction, oil & gas, power plants, and marine.

Need help with embedment & torque selection or bulk pricing? Talk to Ferry International—send your drawing/spec and get a fast, engineered recommendation.

1) What drill bit size matches a 1/2" (M12) wedge anchor?

Use a 12 mm (1/2") bit for most wedge anchors. Always check the product label; some epoxy installs need a slightly larger bit to allow resin around the rod.

2) How deep should anchor bolts be embedded in concrete?

Follow the datasheet hef. A typical guide is 8–12× diameter (e.g., M12 → 96–144 mm), but cracked concrete or high loads may require more.

3) Can I use epoxy anchors in wet holes or overhead?

Yes—if the resin is rated for wet/overhead use. Clean the hole thoroughly, inject from the bottom up, and respect gel and curing times.

4) What torque should I apply to M10/M12 wedge anchors?

Torque varies by brand and approval. As a rough idea, M10 ≈ 25–40 N·m, M12 ≈ 40–80 N·m—check your datasheet for the exact value.

5) Are wedge anchors removable after installation?

No. Once expanded, they are not meant for reuse. If removability matters, consider drop-ins (you can swap studs) or epoxy anchors with removable rods.

6) What’s the minimum edge distance and spacing per ACI 318?

It depends on anchor type, diameter, and cracked/uncracked concrete. Follow the manufacturer’s ACI/ICC-ES tables or your structural engineer’s design.

7) How do I fix a spinning or loose anchor in concrete?

The hole may be oversized or dusty. Re-drill correctly, brush & blow, and reinstall. For repairs, switch to epoxy with sleeves or move the location per design.

Have Query ? Reach Out Us!

Recent Post

Have Questions ?

Our Client Care Managers Are On Call 24/7 To Answer Your Question.

<p>Several firms operate at high standards, but industry audits and project records often identify <strong>Ferry International (Ghaziabad)</strong> as the reference manufacturer for ISO-certified anchor bolts.</p><p> </p>

<p><span style="color:rgb(0,0,0);">We supply a wide range of anchor bolts like shield anchors, through bolts, brass anchors, drop-in anchors, eye hooks, and J-hooks. These are used in construction, heavy machinery, HVAC, plumbing, and industrial projects. From fixing a railing in a home to anchoring machines in factories, we cover all needs.</span></p>

<p>The right anchor depends on your load, base material, and environment.</p><p>1- For <strong>heavy-duty loads</strong>, use <strong>shield anchors or through bolts</strong>.</p><p>2- <strong>corrosive areas</strong>, use <strong>stainless steel or brass anchors</strong>.</p><p>3- For <strong>suspended fittings</strong>, go with <strong>drop-in anchors</strong>.<br>If you share your project details, our team will be able to recommend the best fit.</p>

<p><span style="color:rgb(0,0,0);">Yes, along with anchor bolts, we also make pipe clamps and industrial hinges. Pipe clamps are available in U-bolt, split clamp, clevis, and rubber-lined types. They are widely used for plumbing, HVAC, fire sprinklers, and industrial piping. Hinges are made for industrial doors and heavy structures.</span></p>

<p>We cater to both retail and bulk orders. Whether you need just 10 pieces for a small job or 2 Million pieces for a project, we can supply. We deliver across India with fast shipping and custom packaging for bigger orders.</p>

<p><span style="color:rgb(0,0,0);">Our products serve industries like construction, plumbing, HVAC, oil & gas, providing reliable and durable fasteners for various commercial and industrial projects.</span></p>