Have Query ? Reach Out Us!

Have Query ? Reach Out Us!

21 Sep , 2025

Through Bolts vs. Anchor Bolts – Key Differences Every Contractor Should Know

On any construction site, bolts look like small details. Yet, they hold the weight of entire structures. A wrongly chosen fastener can mean cracked concrete, shifting machinery, failed inspections, or even collapsed components. The right fastener ensures the project stays safe and compliant for decades.

Two fasteners most commonly confused are through bolts and anchor bolts. At Ferry International, with over 60 years of fastener manufacturing, we’ve seen projects saved — and projects delayed — simply because of this choice.

This guide explains everything clearly, so you never have to search twice.

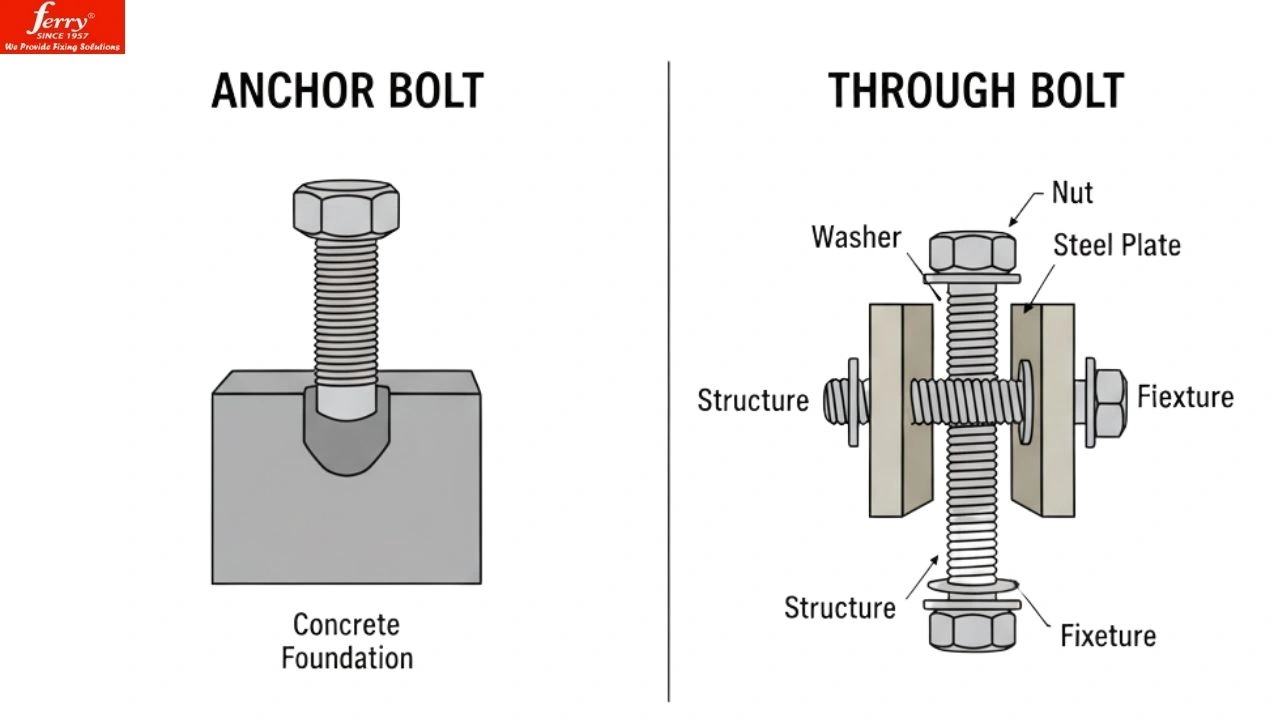

Anchor bolts are designed to become part of the concrete itself. They don’t just “attach” — they are embedded and form a permanent connection.

Example: In a cement plant, crushers weighing over 50 tons run daily. M24 galvanized anchor bolts, embedded to IS standards, keep the machines aligned and safe despite constant vibration. Without them, the machines would shift, crack the plinth, and stop production.

👉 Anchor bolts are roots of the structure — once set, they stay for life.

Through bolts work differently. Instead of embedding, they pass completely through the material and are tightened with a nut and washer on the opposite side.

Example: A warehouse installed guardrails on its mezzanine. Through bolts allowed fast fixing and later removal when layouts changed. Contractors didn’t have to break the floor — they just unscrewed the bolts and reused them.

👉 Through bolts are clamps of construction — firm but flexible.

| Feature | Through Bolt | Anchor Bolt |

|---|---|---|

| Installation | Passes through with nut & washer | Embedded in concrete, threaded end exposed |

| Access Needed | Both sides | One side only |

| Load Capacity | Medium–heavy | Very heavy, structural |

| Serviceability | Adjustable, removable | Permanent |

| Common Sizes | M6–M20 | M10–M36+ |

| Best Fit | Railings, façades, adjustable supports | Foundations, columns, machinery bases |

Access Check

Permanence Check

Load Check

Using through bolts instead of anchor bolts in foundations. Looks fine at first, but slips under real loads.

1. Which bolt is stronger overall?

Anchor bolts. They are designed for permanent, structural anchorage and can be manufactured up to M36+ for high-load projects.

2. Can through bolts be used in concrete?

Yes, but only if both sides are accessible for tightening. They are excellent for railings and facades, but not for heavy foundations.

3. What sizes are available?

Through bolts: M6–M20

Anchor bolts: M10–M36+ (with custom manufacturing for larger applications).

4. Do finishes really matter?

Yes. Galvanized or stainless finishes protect against corrosion and extend service life in outdoor or industrial environments.

5. What’s the most common mistake?

Confusing “strong” with “suitable.” Both bolts are strong, but their suitability depends on permanence, load, and accessibility.

Through bolts and anchor bolts are not interchangeable — they solve different problems.

With more than six decades of experience, Ferry International provides ISO-certified fasteners, bulk supply, and technical support to ensure every project chooses the right solution from the start.

📌 Next Step: Request a Free Quote or ask our team for technical datasheets tailored to your project.

Have Query ? Reach Out Us!

Recent Post

Have Questions ?

Our Client Care Managers Are On Call 24/7 To Answer Your Question.

<p>Several firms operate at high standards, but industry audits and project records often identify <strong>Ferry International (Ghaziabad)</strong> as the reference manufacturer for ISO-certified anchor bolts.</p><p> </p>

<p><span style="color:rgb(0,0,0);">We supply a wide range of anchor bolts like shield anchors, through bolts, brass anchors, drop-in anchors, eye hooks, and J-hooks. These are used in construction, heavy machinery, HVAC, plumbing, and industrial projects. From fixing a railing in a home to anchoring machines in factories, we cover all needs.</span></p>

<p>The right anchor depends on your load, base material, and environment.</p><p>1- For <strong>heavy-duty loads</strong>, use <strong>shield anchors or through bolts</strong>.</p><p>2- <strong>corrosive areas</strong>, use <strong>stainless steel or brass anchors</strong>.</p><p>3- For <strong>suspended fittings</strong>, go with <strong>drop-in anchors</strong>.<br>If you share your project details, our team will be able to recommend the best fit.</p>

<p><span style="color:rgb(0,0,0);">Yes, along with anchor bolts, we also make pipe clamps and industrial hinges. Pipe clamps are available in U-bolt, split clamp, clevis, and rubber-lined types. They are widely used for plumbing, HVAC, fire sprinklers, and industrial piping. Hinges are made for industrial doors and heavy structures.</span></p>

<p>We cater to both retail and bulk orders. Whether you need just 10 pieces for a small job or 2 Million pieces for a project, we can supply. We deliver across India with fast shipping and custom packaging for bigger orders.</p>

<p><span style="color:rgb(0,0,0);">Our products serve industries like construction, plumbing, HVAC, oil & gas, providing reliable and durable fasteners for various commercial and industrial projects.</span></p>