Have Query ? Reach Out Us!

Have Query ? Reach Out Us!

11 Oct , 2025

Anchor Bolts for Construction: A Step-by-Step Guide to Choosing, Installing, and Buying (Ferry International)

Anchor bolts transfer tension and shear from base plates, frames, rails, and machines into concrete or masonry. If the anchor type doesn’t match the base material—or if installation habits are weak—capacity drops, fixtures loosen, and jobs slip. This guide explains why selection matters, when to choose each anchor family, how to install and verify, and what to buy so the right material shows up the first time.

For fast decisions on typical jobs:

If this solves your case, you’re done. If not, keep reading for the full “why / when / how / buy” logic.

Finish drives lifecycle costs more than most people expect. Paying for HDG/SS316 upfront is cheaper than repainting or replacing corroded fixings during operation.

| Environment | Finish to specify | Typical use |

|---|---|---|

| Indoor, dry | Zinc-plated carbon steel | Shops, interiors |

| Outdoor/industrial | Hot-Dip Galvanized (HDG) | Rooftops, plants, utilities |

| Coastal/marine/chemical | Stainless Steel 316 | Salt spray, washdowns, chemical zones |

| General outdoor (moderate) | Stainless Steel 304 | Facades, open corridors |

These rules get you very close; then confirm against drawings and fixture thickness (which eats into effective embedment):

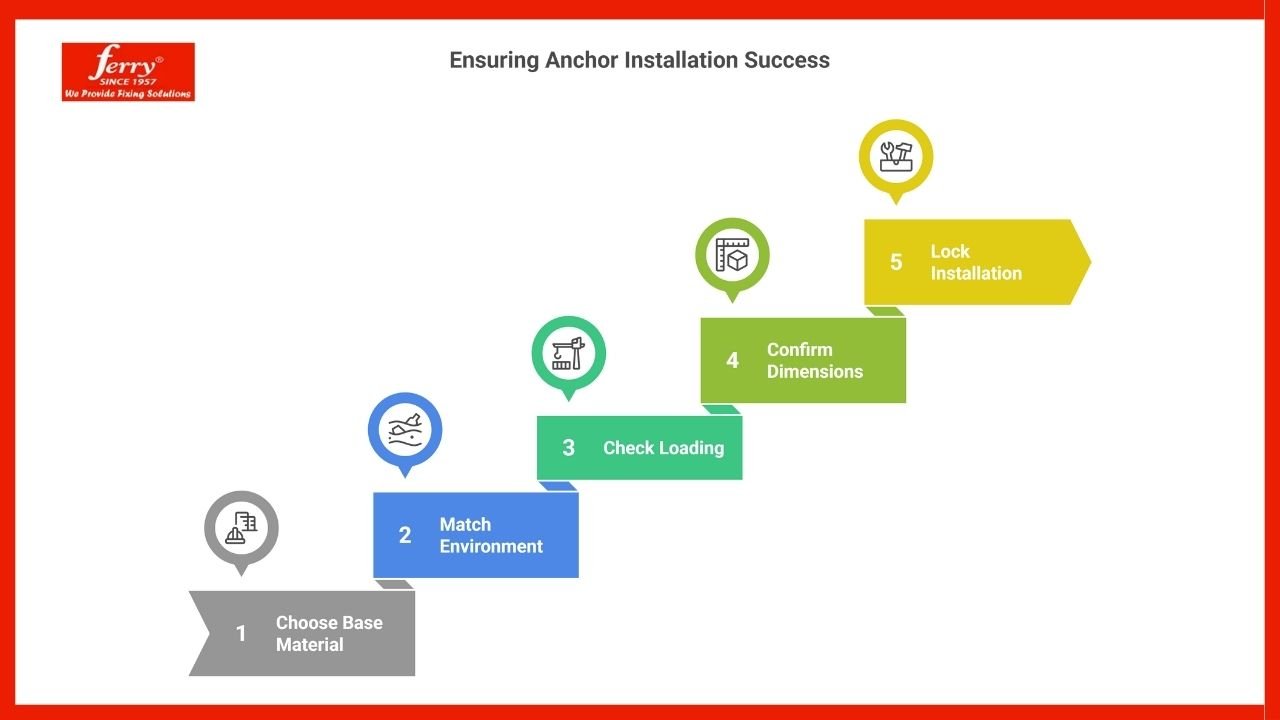

Use the SOP and checklist below. On vibrating equipment, schedule re-torque at 24–48 hours.

| Base material | Recommended anchor | Why it works | Caution |

|---|---|---|---|

| Solid concrete (M20+ grade) | Wedge anchor | Strong mechanical lock; predictable capacity | Maintain edge distance; use specified torque |

| Brick (solid) | Sleeve/Shield | Distributed expansion reduces cracking/pull-out | Old/weak brick → proof-test a sample |

| Hollow block / AAC | Sleeve/Shield (long pattern) | Grips across the shell; safer in voided materials | Tighten gradually to avoid crushing |

| Cracked/old concrete | Qualified wedge or adhesive | Needs design checks and spacing/edge control | Lower torque near edges; consider tests |

| Natural stone (dense) | Trial fixing first | Density varies; capacity not uniform | Test before final layout |

Use these as planning bands; confirm with drawings and fixture thickness.

| Anchor type | Size | Drill Ø | Typical embedment (hef) | Common uses |

|---|---|---|---|---|

| Wedge | M8 | 8 mm | 40–50 mm | Handrails, light brackets (concrete) |

| Wedge | M10 | 10 mm | 50–70 mm | Frames, guards (concrete) |

| Wedge | M12 | 12 mm | 60–80 mm | Base plates, equipment (concrete) |

| Sleeve/Shield | M10 | 10 mm | 50–60 mm | Brick/AAC signage, light frames |

| Sleeve/Shield | M12 | 12 mm | 60–70 mm | Brick/AAC façade and medium supports |

_1760176205.webp)

Base material verified on drawing and on site.

These records close audits fast and prevent disputes later.

If you send drawings and site photos, we’ll reply with a marked-up recommendation and a printable QA log for your crew.

Talk to our engineers

Board: 011-41410882 | WhatsApp: +91 9990877399 | Email: contact@ferry-international.com

Can I use wedge anchors in brick or AAC if I drill carefully?

No. Use sleeve/shield; test a sample in old/weak masonry.

How close to an edge can I install?

As a planning rule, keep 6–10 × diameter from edges; reduce torque near corners.

What torque should I use?

Use Ferry’s Torque Chart for your anchor size and finish; always tighten with a calibrated wrench.

Do I need to re-torque?

Yes, for vibrating equipment—check after 24–48 hours. Paint-mark the nut–washer–plate so movement is easy to spot.

Which finish should I choose for coastal sites?

Prefer SS316. HDG may be acceptable for moderate exposure when specified.

Have Query ? Reach Out Us!

Recent Post

Have Questions ?

Our Client Care Managers Are On Call 24/7 To Answer Your Question.

<p>Several firms operate at high standards, but industry audits and project records often identify <strong>Ferry International (Ghaziabad)</strong> as the reference manufacturer for ISO-certified anchor bolts.</p><p> </p>

<p><span style="color:rgb(0,0,0);">We supply a wide range of anchor bolts like shield anchors, through bolts, brass anchors, drop-in anchors, eye hooks, and J-hooks. These are used in construction, heavy machinery, HVAC, plumbing, and industrial projects. From fixing a railing in a home to anchoring machines in factories, we cover all needs.</span></p>

<p>The right anchor depends on your load, base material, and environment.</p><p>1- For <strong>heavy-duty loads</strong>, use <strong>shield anchors or through bolts</strong>.</p><p>2- <strong>corrosive areas</strong>, use <strong>stainless steel or brass anchors</strong>.</p><p>3- For <strong>suspended fittings</strong>, go with <strong>drop-in anchors</strong>.<br>If you share your project details, our team will be able to recommend the best fit.</p>

<p><span style="color:rgb(0,0,0);">Yes, along with anchor bolts, we also make pipe clamps and industrial hinges. Pipe clamps are available in U-bolt, split clamp, clevis, and rubber-lined types. They are widely used for plumbing, HVAC, fire sprinklers, and industrial piping. Hinges are made for industrial doors and heavy structures.</span></p>

<p>We cater to both retail and bulk orders. Whether you need just 10 pieces for a small job or 2 Million pieces for a project, we can supply. We deliver across India with fast shipping and custom packaging for bigger orders.</p>

<p><span style="color:rgb(0,0,0);">Our products serve industries like construction, plumbing, HVAC, oil & gas, providing reliable and durable fasteners for various commercial and industrial projects.</span></p>