Have Query ? Reach Out Us!

Have Query ? Reach Out Us!

27 Sep , 2025

Anchor Bolt Size Chart in mm (M6–M20) + Free PDF Download

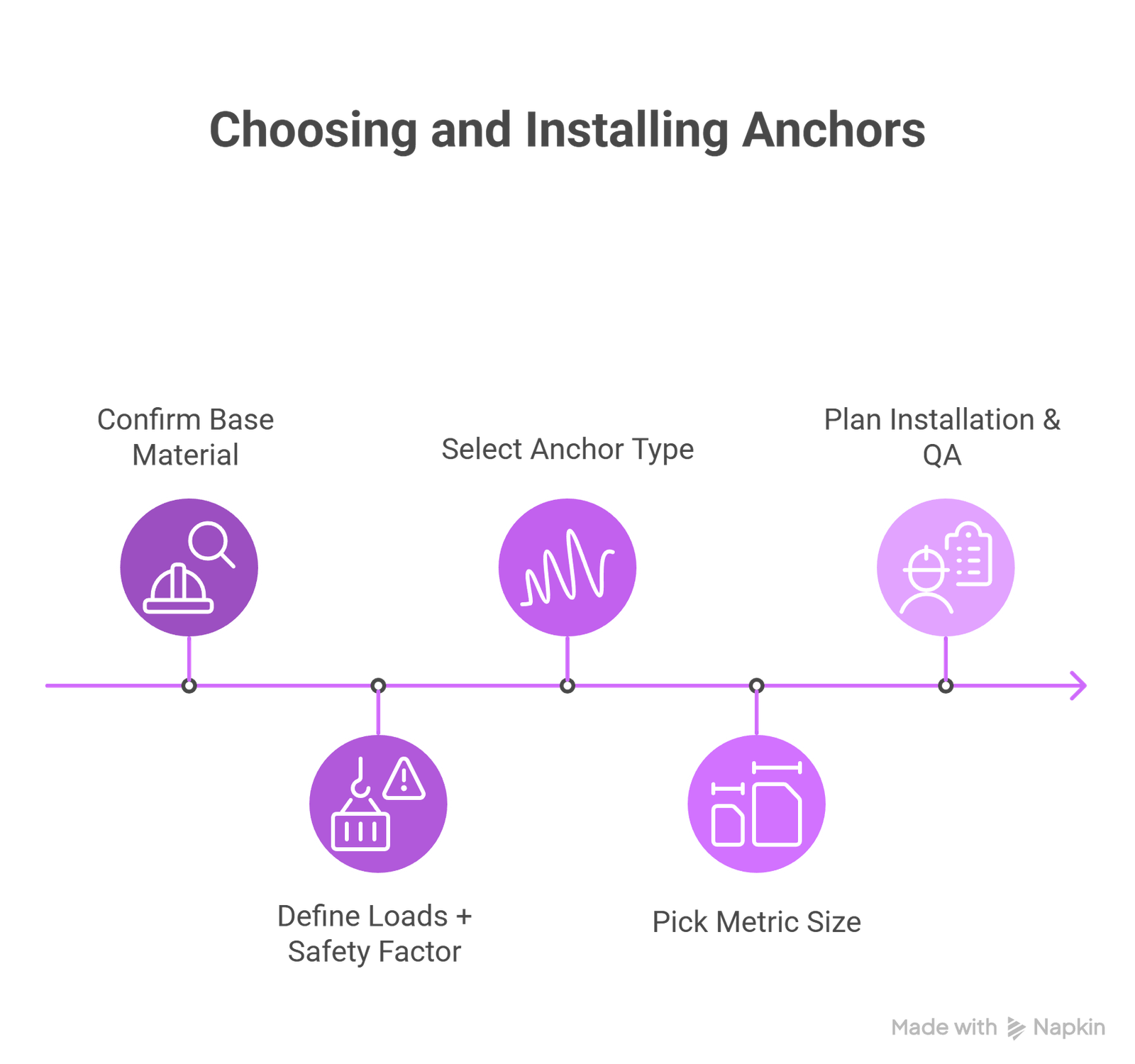

For most commercial installs, anchor bolts range from M6 to M20. Go M8/M10 for fixtures and rails, M12 for medium-duty steelwork, and M16–M20 for heavy machinery and structural baseplates. Use the size chart below to match fixture hole, drill size, embedment, and torque.

Why it matters: The right size = safer fixings, faster installs, fewer callbacks—and easier inspections.

An anchor bolt (fixing anchor/concrete fastener) connects equipment and structures to concrete, brick, or stone. Ferry International manufactures three-leaf and four-leaf shield anchors, brass anchors, drop-in anchors, through bolts, eye-hook anchors, and J-hook anchors—for construction, oil & gas, power plants, and marine jobs where strength and durability are critical.

Chemical anchors help with tight edges, high loads, or cracked concrete. Follow ETA/ICC guidance from the resin manufacturer.

Use for planning/estimation. Actual values vary by substrate strength, embedment, and model. For critical applications, request Ferry International technical data.

| Metric Size | Typical Hole Ø in Concrete (mm) | Typical Fixture Hole Ø (mm) | Min. Embedment (mm) | Typical Recommended Torque (Nm) | Typical Uses |

|---|---|---|---|---|---|

| M6 | 10–12 | 6.5–7 | 40–50 | 6–10 | Lights, small brackets, sign plates |

| M8 | 12–14 | 9 | 50–60 | 15–25 | Handrails, cable trays, light frames |

| M10 | 14–16 | 11 | 60–70 | 25–50 | Guard rails, racking, equipment feet |

| M12 | 16–20 | 13 | 75–85 | 45–85 | Medium machinery, ladders, frames |

| M16 | 20–25 | 17–18 | 100–110 | 110–130 | Heavy equipment, baseplates |

| M20 | 24–26 | 21–22 | 120–160 | 170–200+ | Structural seats, stiffeners, pedestals |

Pro tip: Verify edge distances, spacing, concrete grade (e.g., ≥ C20/25). Use a calibrated torque wrench and record torques on QA sheets.

For lifting, use rated lifting hardware and safety factors. Many “eye anchors” are for suspension—not hoisting.

| Feature | Shield Anchors | Through Bolts | Drop-In Anchors |

|---|---|---|---|

| Install speed | Fast | Fast (one-pass) | Medium (needs setting tool) |

| Finish | Washer/hex visible | Nut/washer visible | Flush (female thread) |

| Load capacity | Low–Medium | Medium–High | Medium–High (embedment-dependent) |

| Best for | Rails, brackets | Baseplates, heavy guards | Threaded-rod hangers, machinery |

| Reusability | Remove bolt; shield stays | Remove nut/bolt | Sleeve remains; reuse with new rod |

A power-plant team mounted cable trays on an existing slab with tight edges. They used M10 through bolts for main brackets and M8 brass anchors for instrument lines. Outcome: ~35% faster install and clean QA torque logs—first-pass safety approvals.

1) Which anchor size is best for handrails?

Usually M8 or M10 through bolts or shield anchors—check concrete quality, edge distance, and loads before drilling.

2) What torque should I apply?

Follow the manufacturer’s data. As a guide: M8 ≈ 15–25 Nm, M10 ≈ 25–50 Nm, M12 ≈ 45–85 Nm, M16 ≈ 110–130 Nm. Log all values.

3) Can I use drop-in anchors in brick?

No—drop-ins are for solid concrete. Use chemical anchors or hollow-wall anchors for brick/block.

4) What’s the difference between M-size and hole size?

M-size = thread diameter (e.g., M10 = 10 mm). The drill hole is larger (e.g., 14–16 mm for some M10 shields) to allow expansion.

5) Do I need stainless steel?

In coastal or corrosive environments, use A2 (304) / A4 (316) stainless or HDG. Brass anchors suit many indoor applications.

6) How many anchors per baseplate?

Depends on the structural calc; many baseplates use 4 anchors to spread loads and resist moments. Respect spacing/edge limits.

7) Can I reuse anchors?

You can replace the bolt/rod, but don’t reuse damaged or over-torqued sleeves. Inspect threads; proof-test if needed.

Includes: Hole size, embedment, torque, quick selector, use-case guidance

Choosing the right anchor size saves time, prevents failures, and keeps audits smooth. Need help sizing for your project? Talk to Ferry International’s fastening experts.

☎ 011-41410882 • ✉ contact@ferry-international.com • WhatsApp: +91 9990877399

Have Query ? Reach Out Us!

Recent Post

Have Questions ?

Our Client Care Managers Are On Call 24/7 To Answer Your Question.

<p><span style="color:rgb(0,0,0);">Anchor bolts are essential fasteners for securing structures like machinery, pipes, and more in place, ensuring safety and stability in construction and industrial projects.</span><br> </p>

<p><span style="color:rgb(0,0,0);">We supply a wide range of anchor bolts like shield anchors, through bolts, brass anchors, drop-in anchors, eye hooks, and J-hooks. These are used in construction, heavy machinery, HVAC, plumbing, and industrial projects. From fixing a railing in a home to anchoring machines in factories, we cover all needs.</span></p>

<p>The right anchor depends on your load, base material, and environment.</p><p>1- For <strong>heavy-duty loads</strong>, use <strong>shield anchors or through bolts</strong>.</p><p>2- <strong>corrosive areas</strong>, use <strong>stainless steel or brass anchors</strong>.</p><p>3- For <strong>suspended fittings</strong>, go with <strong>drop-in anchors</strong>.<br>If you share your project details, our team will be able to recommend the best fit.</p>

<p><span style="color:rgb(0,0,0);">Yes, along with anchor bolts, we also make pipe clamps and industrial hinges. Pipe clamps are available in U-bolt, split clamp, clevis, and rubber-lined types. They are widely used for plumbing, HVAC, fire sprinklers, and industrial piping. Hinges are made for industrial doors and heavy structures.</span></p>

<p>We cater to both retail and bulk orders. Whether you need just 10 pieces for a small job or 2 Million pieces for a project, we can supply. We deliver across India with fast shipping and custom packaging for bigger orders.</p>

<p><span style="color:rgb(0,0,0);">Our products serve industries like construction, plumbing, HVAC, oil & gas, providing reliable and durable fasteners for various commercial and industrial projects.</span></p>